The company Ienai Space is a pioneer in the aerospace industry to achieve the successful launch of the first electrospray-based propulsion system for nanosatellites, setting a new standard for European space propulsion.

Since the birth of the space age in the fifties, thousands of satellites have been launched into the Earth's atmosphere. Currently, there are about 8,000 satellites in orbit, and it is estimated that an average of 2,000 satellites are launched each year. The fact is that the increase in the number of satellites in orbit generates important challenges such as interference with astronomy, environmental problems such as space debris and light pollution in the sky, but the wide range of possibilities for scientific and technological progress is unquestionable.

Satellites play a fundamental role in our daily lives, even if they often go unnoticed: from global communications to climate monitoring and managing emergencies such as fires, these devices are essential. In this sense, the use of nanosatellite networks has turned out to be a great advance for the sector. Unlike a single large satellite, nanosatellites can cover wider areas more effectively. This is particularly relevant, for example, in emergency situations, such as during hurricane seasons, where the ability of these devices to rapidly change position can be vital in providing up-to-date information.

This huge number of satellites are sent into space to perform specific functions in predetermined orbits. In this context, one of the most significant challenges in this operation is the effect of Earth's microgravity and other forces that can alter its trajectory and position in orbit. This problem is exacerbated by the increase in the number of launched satellites discussed above, increasing the risk of collisions between them.

"Unfortunately, society is still not aware of all the work, research and innovation that exists in this regard, since satellites are responsible for the communication networks we use daily, the transmission of meteorological information, freight control, fire or territory control, etc."

Raul Ramos Tweet

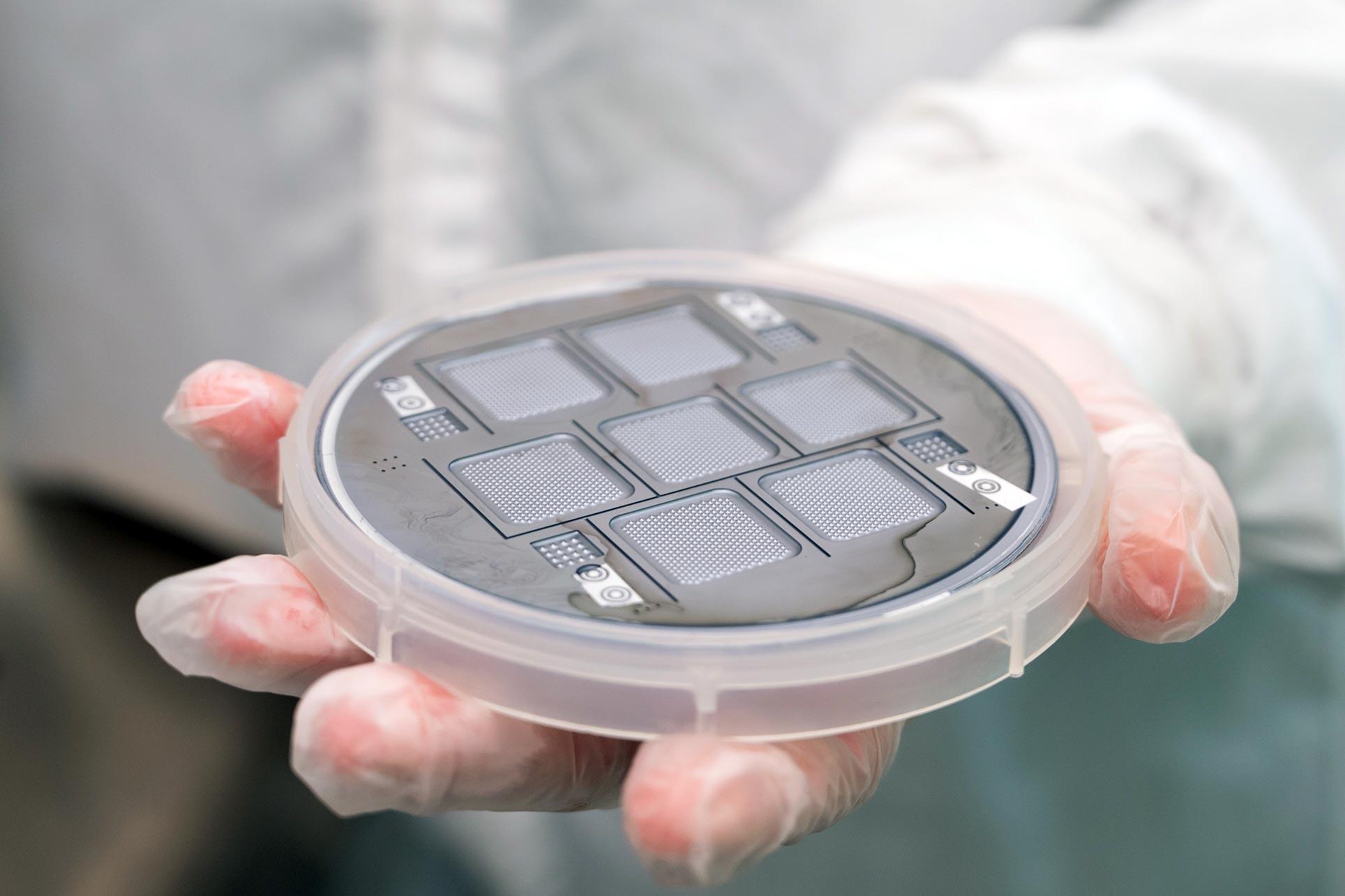

Raúl Ramos, a physicist with a master's degree in nanoscience and advanced nanotechnologies, is the industrial PhD student leading this strategic research project. His main task within the industrial doctorate project is to develop and perfect the nanofabrication of the key components for the electrospra y motor. Ramos' work focuses on Microelectromechanical Systems (MEMS), microscopic components that are essential for the functionality of these new space motors. Thus, research in electrosprays and the manufacture of microelectromechanical systems (MEMS) converge in this project, marking a turning point in research in this field.

Let's go in parts. First, electrospray technology (an existing technique for producing ions, used in methods of analysis of chemical elements) is used to move satellites, and it is a pioneering innovation that works with a special type of liquid called ionic liquid, which serves as fuel. This system uses ionic liquids as fuel, and through the application of a high voltage, generates an electric field that allows the emission of charged particles. These particles are responsible for the impulse needed for the propulsion of the satellite. The most interesting thing about this technology, according to Ramos, is that it can be adjusted in different ways to better adapt to each specific space mission, making it very versatile: "each customer can choose in what range of parameters they want the product to work to adapt to their satellites and the needs of their mission".

On the other hand, MEMS combine microelectronics with mechanics on a very small, microscopic and nanoscopic scale. An example to be able to understand MEMS technology is something that goes unnoticed by most smartphone users: the sensor that causes the screen to change orientation from vertical to horizontal when the phone is rotated. This sensor is a small device inside the phone that can detect changes in position and movement.

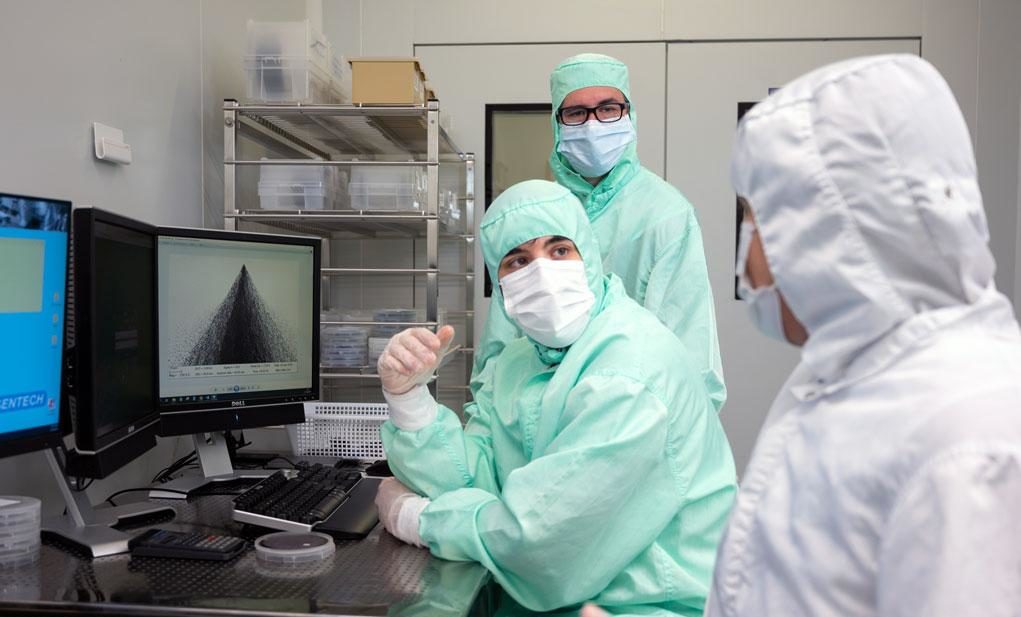

The key to MEMS is their small size, which allows them to be placed in very small spaces, and their ability to perform a wide variety of functions that can only be performed with this technology. It should be noted that this remarkable innovation is not without challenges, since the structures that are part of the ATHENA propulsion system are much smaller than the thickness of a human hair, requiring an extremely controlled manufacturing environment: "for this reason we must work in a clean room, where the number of particles, temperature and humidity are controlled and you have to dress in special equipment so as not to contaminate any stage of the process," says Ramos.

The result of this research has a significant impact beyond the scientific field. Companies dedicated to launching satellites can take advantage of this technology to extend the useful life of their satellites and to make them maneuver effectively in space, thus improving their efficiency and reducing the possibility of collisions. In addition, ATHENA technology can help mitigate the growing problem of space debris, an issue that affects the safety and sustainability of future space missions.

Proof of the impact of the technology derived from this project is the achievements highlighted by Ramos himself: the launch of the first Spanish propulsion system and the first European electrospray propulsion system in October 2022, as well as the successful collaboration with the European Space Agency (ESA) in early 2023.

In conclusion, Ienai Space's ATHENA technology is on its way to becoming a key component in the new era of space exploration, with the potential to radically change how we understand and manage mobility in space. With this advanced technology, the possibilities are as vast as the infinite space that awaits us to explore.